For Domino’s, responsible sourcing means acknowledging the role we play in driving innovation and supplier partnerships to provide the highest quality and safest food possible. We are doing this through our efforts around sustainable packaging, land use, animal agriculture and antibiotics, and food safety, including transparency with nutrition and ingredient information.

SUSTAINABLE PACKAGING

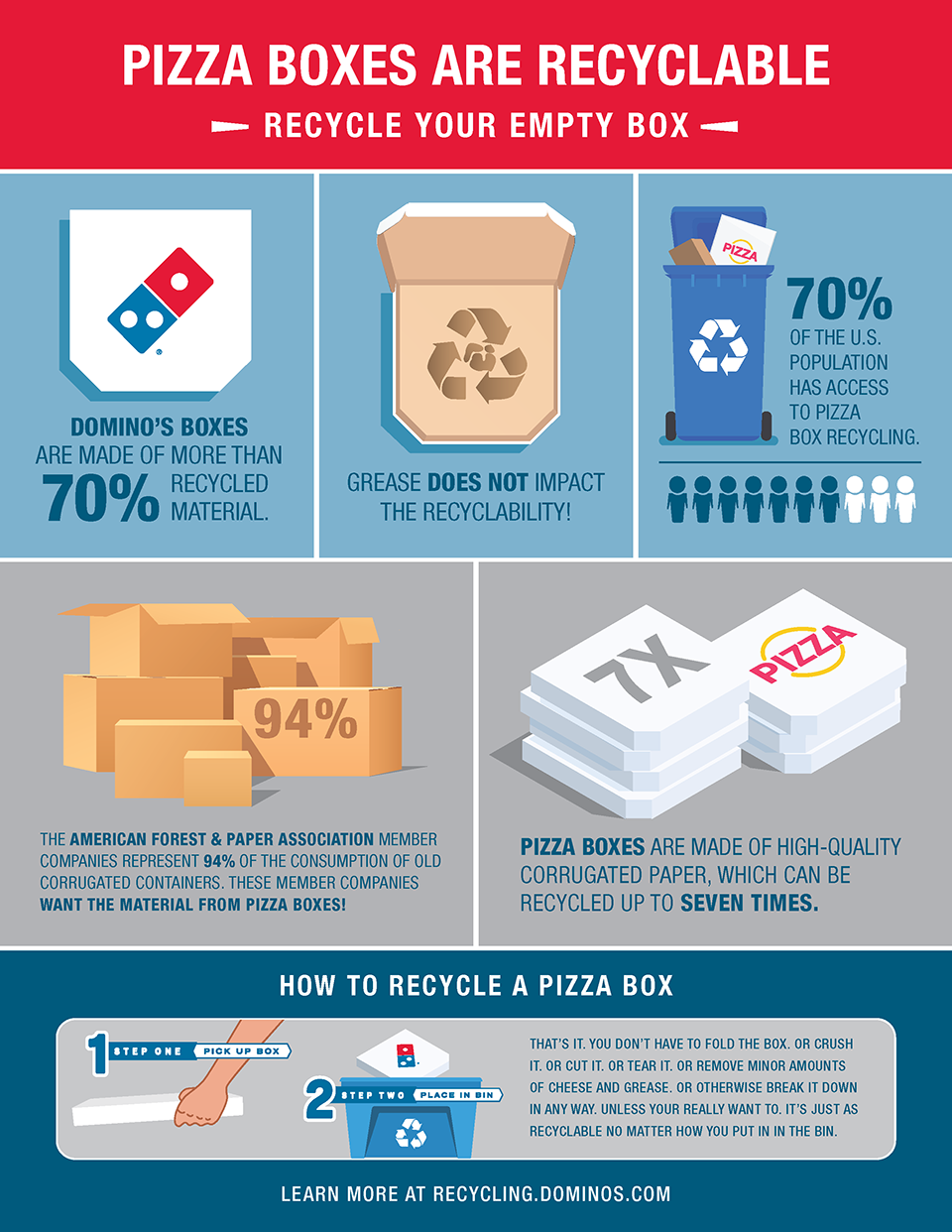

Nearly everything that leaves a Domino’s store leaves in the same type of packaging: corrugated cardboard boxes. Domino’s currently has two corrugated box suppliers, each of which provide boxes made from more than 70% recycled content. Both box suppliers maintain certified fiber sourcing and chain-of custody certifications using third-party audits. For more information, please see our most recent Stewardship Report.

LAND USE

Domino’s has validated near-term and long-term science-based targets (SBTs) which include FLAG (food, land, and agriculture) targets, which are new standards for measuring land-related emissions. Deforestation and land-use change are a large contributor to carbon emissions. Domino’s FLAG-compliant targets represent an important step in managing the deforestation impacts from our supply chain. As such, Domino’s commits to no-deforestation across its primary deforestation-linked commodities, with a target date of December 31, 2025.

Many of our sourcing decisions have been designed to minimize the use of ingredients from areas with high conversion and deforestation risks. We are actively evaluating and assessing other ingredients to ensure they align with our commitment to preventing deforestation. For more information, please see our most recent Stewardship Report.

ANIMAL AGRICULTURE

Domino’s requires that all suppliers comply with USDA regulations on the humane treatment of animals as a baseline for all animal care. It’s important to highlight that Domino’s does not own, raise, transport, or process the animals used for our products. Domino’s purchases pork, beef, and poultry ingredients from suppliers who obtain their products from farmers and ranchers who raise and care for their animals in compliance with local, state, and federal guidelines, industry best practices and the support of farm animal veterinarians. We support the efforts of the dairy industry, at farms both large and small, to use best management practices as outlined by the National Dairy Farmers Organization in the Farmers Assuring Responsible Management (FARM) program. Domino’s has published our animal care principles and continues on a path towards creating an animal care policy for applicable suppliers. For more information, including on Animal Housing, please see our Animal Welfare Principles and our most recent Stewardship Report.

Antibiotics

We care about the food we serve to customers and our families, and we want it to be safe. We also support the care and wellbeing of animals, including those that are sick and may require antibiotics to become well. In recent years, the FDA has enacted regulations that we are happy to support, including rules around what kind of antibiotics farmers can use and when they can use them. No meat in the U.S. food supply can have antibiotic residue in it when it is sold to the public, and we respect the ongoing assessment and regulatory evolution in this area. For more information on antibiotic use within our chicken, pork and beef supply chains, please see our most recent Stewardship Report.

FOOD SAFETY

Domino’s prioritizes serving safe and quality food, and we are committed to protecting Domino’s customers and maintaining their trust. As such, meaningful farm-to-customer food safety and quality standards are a critical part of Domino’s business. Domino’s food safety and quality assurance, supply chain and operations teams work closely with our ingredient and packaging suppliers, distribution facilities, franchisees, and restaurants to source and serve safe and quality food. Additionally, U.S. and Canadian suppliers are expected to adhere to our Supplier Code of Conduct which outlines additional human rights, environmental, integrity and food safety expectations.

Transparency is an important component of trust, and we provide an online list of our ingredients and allergens for the products Domino’s sells. We also provide a nutrition calculator on dominos.com that can provide full nutrition information on the millions of combinations of products on our menu. For more information, please see our most recent Stewardship Report.