For Domino’s, our environmental aspiration is to be good stewards of the natural resources that feed the power of possible throughout our value chain, each and every day. Our aim is to help improve our fair share of the planet’s health through the choices we make and the way we operate our business.

We focus on climate, water, waste and packaging through the lens of our core businesses – our supply chain centers where we make pizza dough and distribute other foodstuffs, our corporate-owned stores and offices. By working to partner across our value chain, we strive to ensure that our practices not only support our business but also contribute positively to the planet's long-term health.

CLIMATE

The foundation of our approach to climate is our corporate carbon footprint, which accounts for greenhouse gas emissions across our entire value chain. Using an operational control approach aligned with the Greenhouse Gas Protocol (GHGP), we measure:

- Scope 1 emissions from direct operations, such as fuel used by our fleet;

- Scope 2 emissions from purchased electricity, steam, heating, and cooling;

- Scope 3 emissions—including both FLAG and non-FLAG categories—that we influence indirectly through our relationships with suppliers and franchisees.

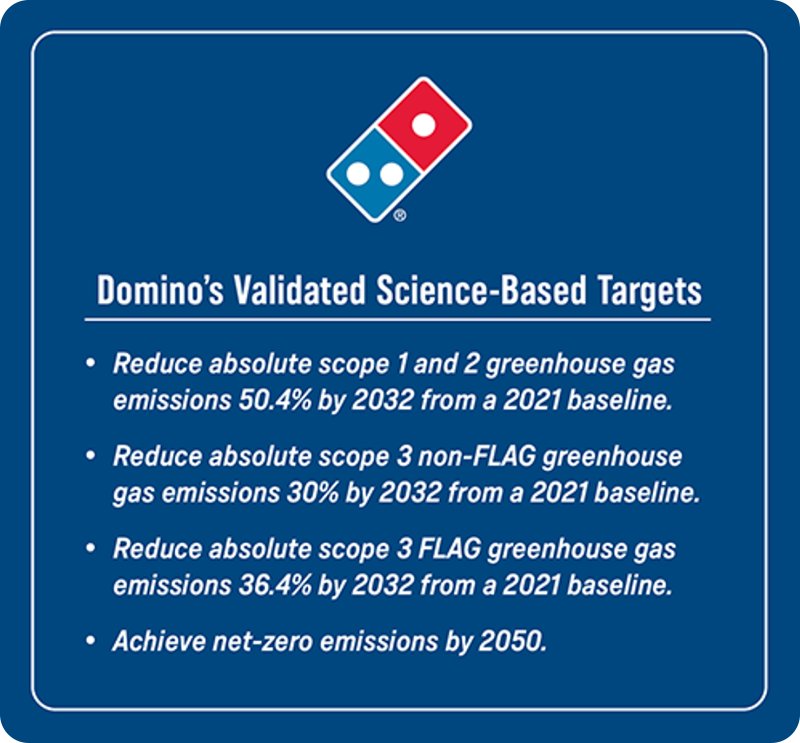

Domino’s climate action is guided by our near-term and net-zero emissions reduction targets, which are aligned with and validated by the Science Based Targets initiative (SBTi). In addition to our standard emissions reduction goals for Scope 1, 2, and 3, these targets include specific commitments to address emissions from the Forest, Land and Agriculture (FLAG) sector—one of the most climate-impacted and emissions-intensive areas of our value chain. Domino’s is proud to be the first U.S. pizza company to receive validation for FLAG targets. We are collaborating across our Company to identify and enhance strategies that are designed to help us achieve our targets. For more information, including details about our No Deforestation Commitment & Policy, please see our most recent Stewardship Report.

WATER

Water is critical to our business as a raw material for our dough and other ingredients, but also for the safe and effective ongoing operations of our cleaning and processing activities. Domino’s operational water consumption trends align with our business volume and are generally from municipal sources. For more information, please see our most recent Stewardship Report.

WASTE & PACKAGING

As the No. 1 pizza company in the world, we recognize the importance of continuously evolving and innovating our waste management practices and are exploring ways to reduce waste and improve packaging throughout our value chain. Supply chain center and store operations produce a variety of waste streams, such as dough and other organics, cardboard, plastic, and wood. We continue to investigate ways to reduce operational waste through improved product forecasting, supplier packaging efficiencies, and operational changes to further leverage existing untapped opportunities. Additionally, our pizza and other consumer product boxes are made utilizing recycled content, and since 2022 we have encouraged consumers to recycle the boxes. To learn more about consumer packaging recycling at https://recycling.dominos.com/. For more information, please see our most recent Stewardship Report.